The humidity and temperature of the cellar are two important parameters. If you are interested in a cellar for wines, cured meat or cheeses, you can’t ignore these elements if you want to obtain an environment that guarantees you quality conservation.

Wine cellar temperature and humidity

Wine is not an inert liquid, but it is alive and particularly sensitive to environmental conditions. If these are not optimal, it might get spoiled: it risks loosing taste, color and other characteristics.

This is why it is essential to make the wine cellar an ideal habitat for our precious bottles.

What do you need to pay close attention to?

Wine cellar temperature

The first thing to know is this: the wine fears the sudden change of temperature. Unfortunately, this happens very often, especially during season change. This is a very serious problem for vintage bottles.

For this reason, high-level cellars are always shielded, in this way they are not affected by the outside temperature. The underground cellars are perfect because they are protected directly from the earth, which is an excellent insulator!

Unfortunately, however, the simple isolation of the cellar is not necessarily sufficient to keep our wine safe. In fact, the temperature inside it must remain within an optimal range.

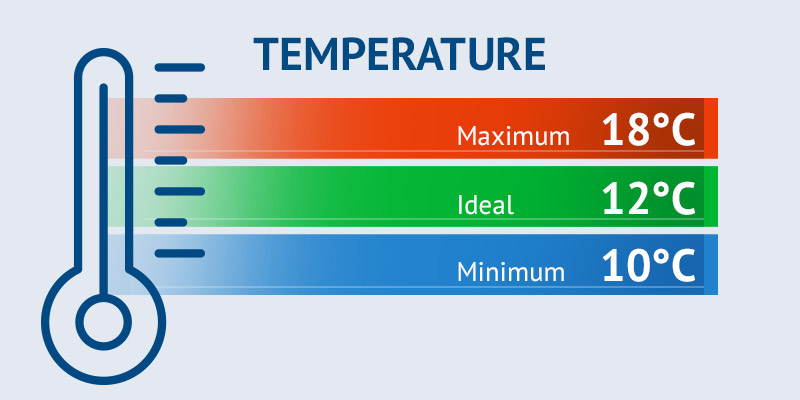

The ideal wine cellar should have a controlled temperature around 12°C. This may vary slightly according to the type of wine (red, white, sparkling, still, etc.). However, temperatures ranging from a minimum of 10°C to a maximum of 18°C are acceptable, as long as they are constant.

Wine cellar humidity

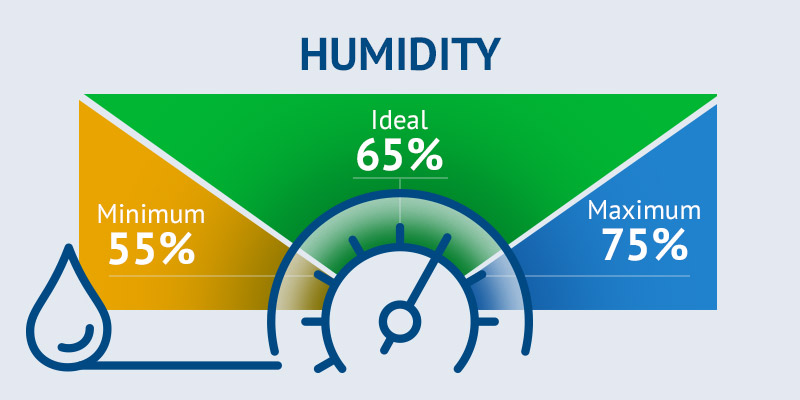

Humidity also plays a fundamental role in the conservation of wine. This doesn’t seem intuitive to many people because the bottles are sealed and therefore their content do not come into contact with the external environment. In reality the bottles are closed with a material, cork, which perfectly preserves the wine but is also very sensitive to humidity.

If humidity is too low, the cork dries up and loses its elasticity: it is no longer watertight and the wine can leak out and evaporate or oxygen can penetrate the bottle. If the humidity is too high, mold can form on the cork and the label, but this does not affect the quality of the wine.

The ideal humidity of a wine cellar should be between 55% and 75% and never go beyond these values.

Other factors to consider

In addition to temperature and humidity, it is good to keep the bottles away from light and vibration. In fact, these two elements affect the microbiological processes of wine, altering its taste and nutritional quality.

Cured meat cellar temperature and humidity

The conservation process of cured meats is an integral part of their preparation.

After being bagged, in fact, the cured meat is stored to get its characteristic taste. It is very important to maintain the right conditions so that the seasoning takes place correctly, otherwise not only the taste is affected but also the quality of the product itself. A cured meat stored in the wrong conditions can lose quality such as colour or taste, or even lose its edibility.

Ideal conditions for the seasoning of cured meats

I salumi passano attraverso 3 fasi di preparazione:

- Stewing. In this phase, which lasts a few days, the harmful bacterial flora is eliminated, the benevolent one is flavoured, and the biochemical processes that transform the meat into salami begins.

- Drying. In this phase the temperature is lowered, as well as the humidity rate.

- Seasoning. This is the longest phase, and corresponds to the long-term storage of the product. The temperature and humidity are lowered even further.

These phases are found in the preparation of all cured meats, but the parameters depend a lot on the type of meat.

Ideal temperature and humidity for cured meats cellar

In the case of the classic salami, that is raw pork sausages, here are the temperature and humidity parameters to be respected to obtain a quality product:

| PHASE | TEMPERATURE | HUMIDITY | DURATION |

|---|---|---|---|

| Stewing | 18-25°C | 84-90% UR | 1-4 days |

| Drying | 11-14°C | 70-80% UR | 5-10 days |

| Seasoning | 10-14°C | 65-75% UR | 30-70 days |

Source: Zeppa, G. Appunti di tecnologia dei salumi, Università di Torino.

Cheese cellar temperature and humidity

Like cured meats, cheese also needs to be aged in a cellar with the right temperature and humidity conditions.

During the delicate maturing process, the milk is completely transformed. The dough becomes compact, loses weight and humidity. The phenomenon of lipolysis is activated, which transforms milk fats into proteins. These fatty acids, released during the phenomenon, influence the aroma of various types of cheese both as directly, as occurs in Italian varieties, in which short-chain fatty acids are directly responsible for taste and aroma (Woo et al., 1984; Addis et al., 2005a; Addis et al., 2005b; Pirisi et al., 2007), and as precursors of other compounds.

IIn addition, the sugars ferment, forming the gases that create the classic holes in the cheese that are an advantage in some varieties and a defect in others, and, of course, the characteristic flavour that makes the cheese special is formed.

All these elements are strongly influenced by temperature and humidity.

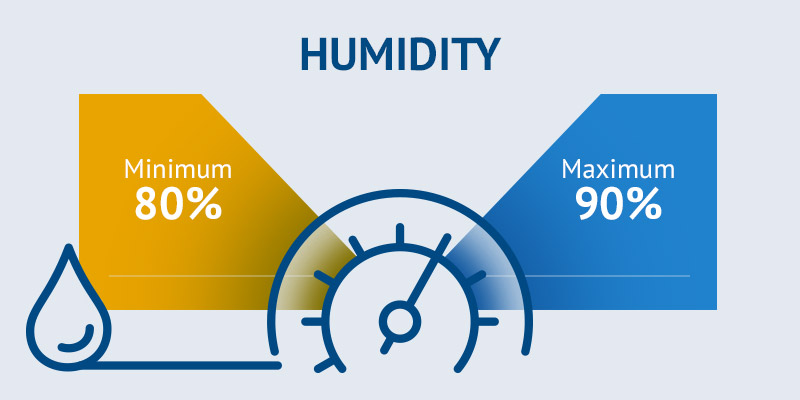

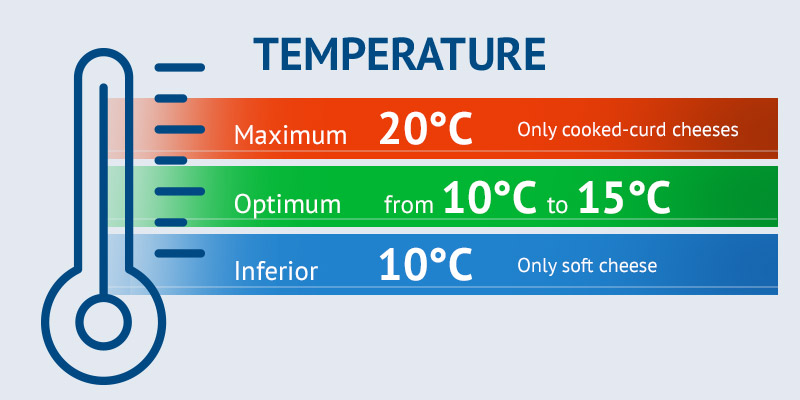

Ideal humidity in the cheese cellar

Cellars are generally used with an air humidity rate between 80% and 90%.

Ideal cheese cellar temperature

The ideal temperature of a cheese cellar is between 10°C and 15°C

However, the maturation of some types of cheese is significantly different from these parameters.

- Soft cheeses such as Gorgonzola, Calembert and Stracchino, require cellars with lower temperatures (from 5°C to 10°C).

- Cooked cheeses,such as Montasio, Piave or Bitto, require cellars with higher temperatures (from 12°C to 20°C).

Recreating the right temperature and humidity conditions in a seasoning cellar allows the proliferation of the microbial flora that acts in the seasoning processes. In short, lthe cheese cellar is a real ecosystem with its own delicate balance. A small oscillation in humidity or temperature is enough to ruin the proportions between the various species of mold and bacteria, with a negative impact on the taste of the cheese.

This is why it is essential to keep the humidity and temperature conditions of a seasoning cellar constant.

Controlling the temperature and humidity of a cellar: a real case

So far we have talked about the ideal conditions of temperature and humidity of the cellars. But how does this system works in practice?

Here is an example we have drawn from our case studies.

BACKGROUND

An important consortium of food producers located in Northern Italy needed to make sure that the ham didn’t get moldy during its ageing especially in all the parts where they applied the lard.

Tecnosoft, as a consultant, has been contacted to study the problem and to design a solution that warns the producers when the curing room conditions are proximal to the development of mold.

PROBLEM ANALYSIS

Tecnosoft Team has examined the place. After the meeting with the producers Tecnosoft had all the information to understand that monitoring temperature and humidity wasn’t enough. It was necessary supervising the dew point through a specific sensor.

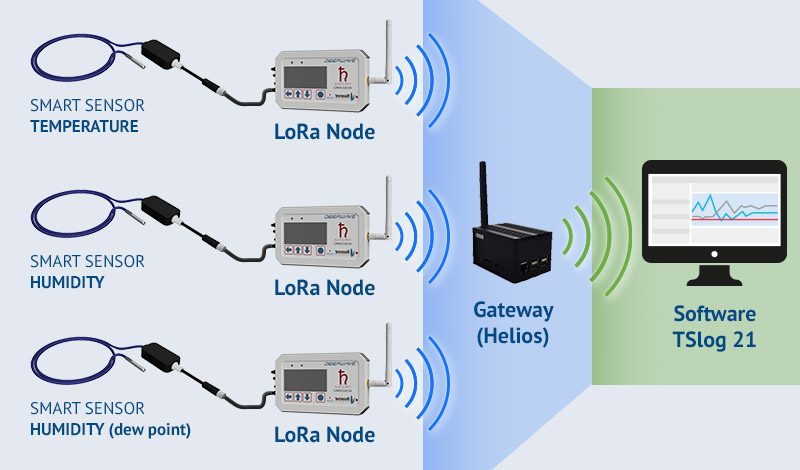

SOLUTION

Tecnosoft decided that the solution was the installation of DeepWave Nodes that are part of a new radio system that allows the real time monitoring based on LoRa Protocol. Thanks to the long distance data transmission it was possible using just one Helios receiver to cover the whole area of each producer. Various radio sensors were located in different rooms to register temperature and humidity by means of innovative Smart Sensors that allows a rapid recalibration of the system.

This solution was customized through the development of a Smart Sensor capable of measuring the dew point directly without resorting to the software.

Used devices

Smart Sensor for temperature and humidity measurement

The Smart Sensor is the device that collects environmental temperature and humidity data. Its task is to collect data from the environment and send it to the LoRa Node of the DeepWave system.

For the salami cellar project we have also developed a customized model that measures the dew point (the state of air in which water vapour condensation occurs).LoRa node

The LoRa node is the data collection unit of the DeepWave system. The smart sensors, connected by cable to the Node , send the monitoring data of temperature, humidity and dew point.

The Node then sends the collected environmental data by the external antenna via radio, using the LoRa Protocol from which it takes its name.

Gateway - remote data transmission

Helios is the device that receives data via radio from LoRa Nodes and sends them to the TSLog21 software database.

It is therefore the key point where all the collected monitoring data in the cellar converge, and from which they are sent for viewing.

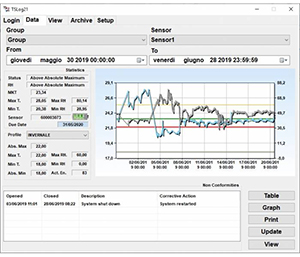

Software for temperature and humidity monitoring

The TSLog21 software allows complete monitoring of the entire DeepWave system from a computer, smartphone or tablet. Through TSLog21 it is possible to consult the monitoring data of the cellars, print the reports, export them to Excel, manage the users enabled to view and receive notifications, and much more.

Working flow

Other applications

The DeepWave monitoring system is not just a great solution for ham ageing but it’s also perfect for cheese ripening and for wine cellars.

Are you interested in our solution for cellar humidity and temperature monitoring?

Flip through our history

Flip through our history