Whether you have a food oven or you manage industrial ovens, you know how important it is to keep temperature under control.

If temperature does not remain within its optimal range, the quality of the products you produce can be severely affected.

Monitoring the temperature in an oven is a rather complex operation that requires, in addition to the installation of the measurement system, a thorough knowledge of the temperature cycles and heat resistance of the equipment used.

The end of the data logger in the oven

Some time ago, a customer dealing with industrial furnaces approached us to monitor the temperature during the production processes.

It was the first case of this type that was requested to Tecnosoft, but for us it was not a problem, quite the contrary! In fact, our company modus operandi has always been based on testing new solutions.

We proposed our TC-Log 8 data logger, designed to withstand very high temperatures, around 130°C. The customer used it directly in the oven, without any protection, not being well aware of the thermal curve that the oven would follow.

At the first measurement, the data logger had suffered irreparable damage precisely because it was used extensively out of specification. The customer contacted us describing the problem and asking us to find a solution to protect the logger from excess heat.

But how?

Sensor with probe: the logger as an oven thermometer

The main problem in measuring and monitoring the temperature in very hot environments is the electronics. In fact, the circuits in general can work without problems up to relatively high temperatures but the more the temperatures increase, the more the stress of the electronic components increases and the malfunctions increase, up to the complete electronic blackout. This was exactly what happened to our logger.

The first idea was to evade the problem. We would have kept the data logger outside the oven while a probe with built-in sensor would have remained inside. Some sensors, unlike electronic components, are built to withstand very high temperatures and the materials with which they are assembled do not deform or burn. As a result, they can also be used in extremely hot environments.

This solution is very practical. It is no coincidence that the probe equipped with a sensor is one of the most common high temperature measurement systems. The oven thermometer that is commonly used in the kitchen to measure the internal temperature of cooked meat is based on this principle. Simply insert the appropriate probe inside the dish whose temperature you want to know, without the need to bring the logger close to the heat source but rather keeping it out of the oven at room temperature.

Unfortunately, in our case we could not apply this system, as we could not drill the oven.

This operation would have resulted in two problems:

- the exchange of air with the outside, which is not compatible with many types of industrial ovens. In fact, dust and humidity penetrate from the holes which can compromise the success of the process

- modifying the furnace for monitoring purposes was neither technically possible nor economical.

In our case it was therefore necessary to keep the data logger inside the oven... which, however, has much higher temperatures than the logger can withstand. A nice dilemma, but one that can be managed by means of thermal protection.

The thermal protection for data loggers

The new test provided that the logger was placed in a special thermal case, that is, an armature of insulating material to protect it from high temperatures. Positioned outside the housing, the sensor is in contact with the ambient temperature of the oven and can transmit data to the logger which in the meantime it is closed in a cooler environment.

Having found the trick, we just had to find the insulating material.

Test n ° 1: the void

The void is the insulation par excellence. This is notorious for anyone involved in the physics of heat. In fact, heat behaves like a vibration that is transmitted by contact from molecule to molecule. If the molecules are not there, there simply cannot be heat transmission. The heat transmitted by radiation is reduced making the surfaces reflective. Consequently, vacuum is the number one insulator for a large number of applications. The typical case is that of the thermos.

A completely empty metal container, deprived of all air, can shield the temperature for a long time, protecting the data logger. Our company offers vacuum-shielded thermal protections, which are suitable for many applications but also have a weakness: they do not withstand high pressures.

The high pressure air, pressing hard on the walls of the dewar (the common thermos), ends up overcoming the resistance of the case, crushing the walls of the dewar. The data logger inside risks not only losing its heat protection but can be damaged and stop working.

Test No. 2: water

Water, in addition to being an extremely abundant and inexpensive substance, is one of the best thermal accumulators. In fact, in addition to having a high specific heat, until evaporation is completed, it guarantees a constant temperature of 100°C and our logger withstands 130°C. However, it is necessary to ensure that the steam that is generated can find an outlet somewhere otherwise there would be an increase in pressure with a consequent increase in the evaporation temperature and risk of deformation of the protection, this time due to internal pressure, or failure of the electronics. Therefore, it must be acceptable that there is a leak of steam during the process and, therefore, it cannot be used for all processes that do not allow air circulation.

Test No. 3: the Teflon

Having discarded both vacuum and water, our attention focused on Teflon®. Famous for being used to coat nonstick pans, it is a material with extraordinary features. First, it is chemically inert toward most substances. Other positive features are its high specific gravity and high specific heat, making it an excellent heat absorber. This works in our favor: unlike water, a Teflon component would not affect the oven environment in any way.

The most interesting aspect, however, is its exceptional heat resistance: it remains unchanged at temperatures up to 250°C. It only begins to decompose at temperatures above 400°C, which is enough to melt lead!

So Teflon is all in all a good insulator. But there was another material worth trying-and one that left us speechless!

Test No. 4: the airgel

In our tests, the airgel proved to be the best insulation material ever. This very special substance has very unusual qualities.

Born in 1931 as a bet between two chemists, it is currently used, among other things, by NASA as a heat shield in the re-entry Space Shuttle.

From a chemical point of view it is a mixture of gas and solid. In fact it is a gel, but in which the liquid has been replaced by a gas. To the touch, it is similar to a light sponge although, from a chemical point of view, it is closer to glass than to plastics. However, the airgel is much more flexible than glass and is also much more resistant, being able to withstand enormous load capacities. It is made up of 99.8% air and 0.2% silicon, which explains its extreme lightness.

Airgel is an exceptional thermal insulator. There are really impressive videos on Youtube showing this property. By applying open flames under a thin layer of airgel, it takes several minutes to heat the objects placed on top.

Airgel is generally not sold in its pure state, but is used in panels, in association with reinforcing fibers to promote flexibility and durability.

Our test carried out with airgel panels confirmed that this type of coating guarantees the best insulation of the internal logger.

Unfortunately, the airgel has a major flaw: it releases dust that can affect the process.

Test n ° 5: silicone and expanded clay

The problem at this point is to find a compromise that satisfies the requirements of isolation and not the release of substances that can affect the process. This compromise has been found, for now, in a mix of expanded clay incorporated in silicone. Expanded clay is an excellent thermal insulator and silicone a good thermal buffer. The mix resists over 300°C.

Our thermal box for TC-Log 8 loggers was finally ready. But our work wasn't done yet.

The thermal curve

Let's start with an assumption that we already know: the TC-Log 8 logger withstands up to 130°C. So the temperature of the logger itself, without the case, can reach this temperature while maintaining the ability to function. We have a case with silicone insulation + expanded clay that manages to significantly delay the internal overheating of the logger.

What we now need to check is how much we manage to delay reaching the critical temperature of the logger inside the insulating case.

Then, we bake the logger enclosed in the case and subject it to different temperatures.

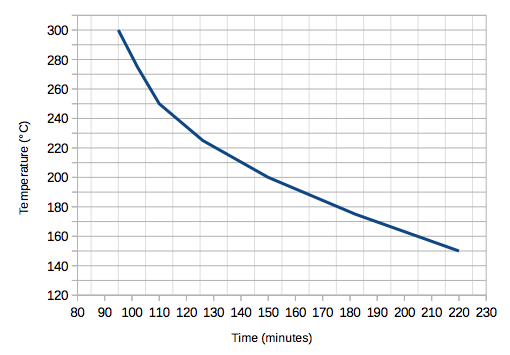

By repeating the test at different temperatures, we verify what was expected, that is, the higher the temperature, the less time it takes for the logger to warm up. Specifically, we now know that:

- At 300°C the logger reaches critical temperature in 95 minutes

- At 200°C the logger reaches critical temperature in 150 minutes

- At 150°C the logger reaches critical temperature in 220 minutes

These data will allow us to understand the general resistance of thermal protection to exposure to high temperatures. Basically, we know how long we have to wait to remove the logger from the oven before it gets damaged.

But be careful! There is another element to consider.

A prudent advance to avoid overshoot

When the data logger is removed from the oven, the overheating phase is not over!

In fact, the insulating material of the housing continues to heat the data logger for a few minutes after it is removed from the oven.

Although it seems paradoxical, this phenomenon has a simple scientific explanation.

Inside the oven, the insulation molecules are continuously stressed by the heat. The closer the molecules are to the outside, and therefore to the heat source, the more they are stressed. Thus, we will have the outer layer of the insulation warmer, and the inner layer colder. As time passes, the external molecules continue to transmit heat inwards. After taking the logger out of the oven, the warmer molecules in the outer layer begin to cool down, but at the same time they continue to give their heat to the colder inner molecules, which then continue to heat up for some time.

This is why it is important to remove the data logger from the oven a little before reaching the maximum peaks of the thermal protection curve. From our tests, we calculated an ideal deviation of 10-15 minutes.

If you need to measure the temperature of an oven, ask Tecnosoft! Thanks to our experience, we will be able to guide you in managing your data loggers for measuring high temperatures.

By analyzing the starting situation and carrying out targeted tests, we will create a monitoring system for you that allows you to obtain precise data in the most efficient way.

Flip through our history

Flip through our history